A laboratory spray dryer is a small-scale drying system that is commonly used in research and development, as well as quality control testing in the food, chemical, and pharmaceutical industries. It works by atomizing a liquid feed into a fine mist, which is then dried by contact with hot air to form a solid powder.

There are several types of laboratory spray dryers available, including:

Rotary atomizers: These use a high-speed spinning disc to break up the liquid feed into droplets. They are commonly used for drying heat-sensitive materials.

Nozzle atomizers: These use a high-pressure gas or compressed air to break up the liquid feed into droplets. They are commonly used for drying abrasive or highly viscous materials.

Fluidized bed atomizers: These use a bed of hot air to fluidize the liquid feed, which is then atomized by a high-speed gas or compressed air. They are commonly used for drying hygroscopic or sticky materials.

When selecting a laboratory spray dryer, it is important to consider the following factors:

Production capacity: The capacity of the spray dryer should be sufficient to meet the needs of your application.

Spray drying chamber: The chamber should be made of materials that are resistant to corrosion and able to withstand high temperatures.

Atomization method: The atomization method should be suitable for the type of liquid feed being used.

Temperature control: The spray dryer should have precise temperature control to ensure that the drying process is consistent and efficient.

Safety features: The spray dryer should have safety features such as over-temperature protection and explosion-proof construction to ensure the safety of the operator.

Ease of use: The spray dryer should be easy to operate and maintain, with clear instructions and user-friendly controls.

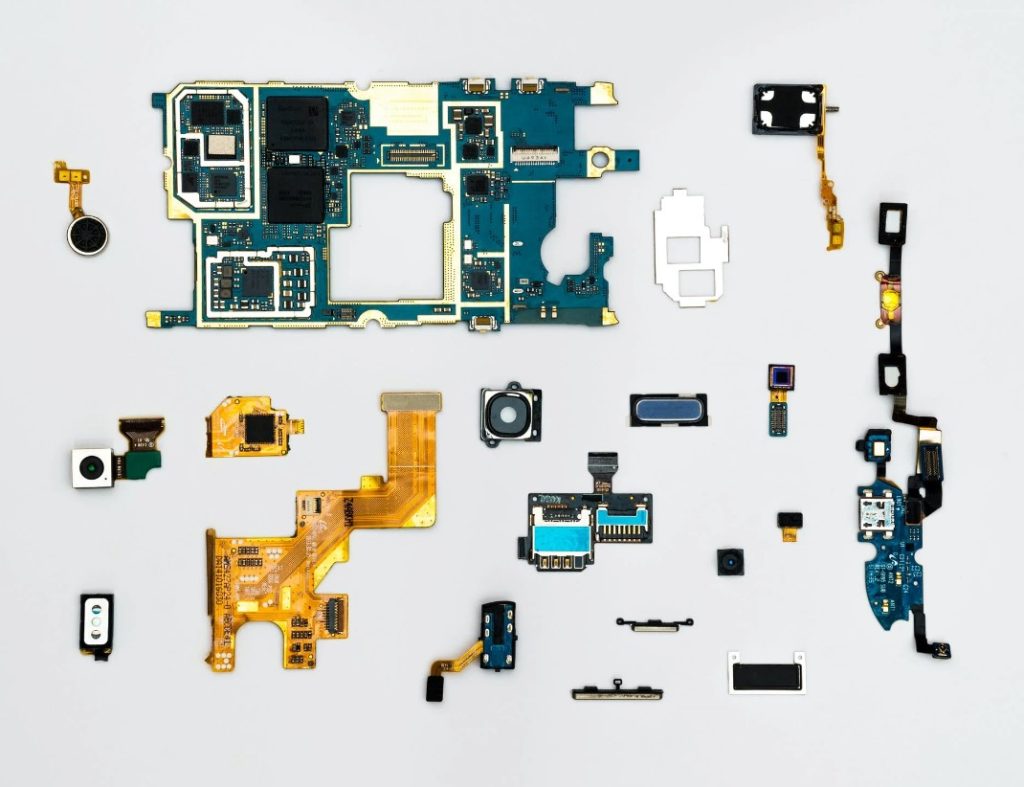

What are the Laboratory spray dryer parts and function?

Here are the main parts of a Laboratory Spray Dryer and their functions:

Atomizer: This is the device that breaks the liquid feed into a fine mist or spray. There are several types of atomizers, including rotary atomizers, nozzle atomizers, and fluidized bed atomizers.

Drying chamber: This is the enclosure where the drying process takes place. It is typically made of stainless steel or other corrosion-resistant materials.

Inlet and outlet: These are the openings through which the liquid feed and hot air are introduced into the drying chamber.

Heating element: This is the device that generates the hot air used to dry the liquid feed. It can be a gas burner, electric heater, or steam generator.

Temperature controller: This is the device that regulates the temperature of the hot air in the drying chamber.

Fan: This is the device that circulates the hot air in the drying chamber and helps to evenly distribute the atomized droplets.

Collection system: This is the device that collects the dried powder as it is produced. It can be a cyclone, bag filter, or centrifugal separator.

Control panel: This is the central control system that allows the operator to adjust the operating parameters of the spray dryer, such as the atomization rate, drying temperature, and airflow rate.

Safety features: These are the devices that protect the operator and equipment from hazards such as explosions, fires, and overheating. They can include explosion-proof construction, over-temperature protection, and emergency shutdown systems.

What is the pressure of Laboratory spray dryer?

The pressure of a laboratory spray dryer depends on the type of atomizer being used. Nozzle atomizers typically operate at higher pressures, while rotary atomizers and fluidized bed atomizers operate at lower pressures.

Nozzle atomizers use a high-pressure gas or compressed air to break up the liquid feed into a fine mist. They typically operate at pressures ranging from 50 to 250 psi (pounds per square inch).

Rotary atomizers use a high-speed spinning disc to break up the liquid feed into droplets. They typically operate at pressures ranging from 5 to 50 psi.

Fluidized bed atomizers use a bed of hot air to fluidize the liquid feed, which is then atomized by a high-speed gas or compressed air. They typically operate at pressures ranging from 5 to 20 psi.

It is important to note that the pressure of the atomizer should be matched to the viscosity and surface tension of the liquid feed being used. Higher pressures may be required for drying highly viscous or abrasive materials, while lower pressures may be sufficient for drying thin, low-viscosity liquids.

Where are Laboratory spray dryers used?

Laboratory spray dryers are commonly used in research and development, as well as quality control testing in the following industries:

Food industry: Laboratory spray dryers are used to dry food products such as Milk powder, dried eggs, coffee and fruit juices, Infant food, cake mixes as well as to produce food additives and ingredients such as sweeteners, flavors, and color,animal feed, Encapsulation of flavors and Bioactive compounds. Nutritional oils or yeasts

Chemical and Cosmetics industry: Laboratory spray dryers are used to dry chemicals such as pigments, paints and dyes, detergents, soaps catalysts, and surfactants, Pesticides, herbicides as well as to produce fine chemical products such fertilizers and agrochemicals and fungicides, insecticides.

For nanomaterials that are used for automative parts,turbine engines titanium and zirconia implants,advanced ceramics and carbides.

Pharmaceutical industry: Laboratory spray dryers are used to granulation, encapsulation and to dry pharmaceutical products such as antibiotics,vaccines, APIs (active pharmaceutical ingredients), excipients,vitamins,yeast and nutraceuticals, as well as to produce drug delivery systems such as microencapsulation.Bio products suach as: enzymes, hormones,proteins

And peptides

Other industries: Laboratory spray dryers are also used in a variety of other industries, including Ceramic materials, nano materials, batteries, energy, environmental, and materials science.

In addition to their use in industrial settings, laboratory spray dryers are also used in academic and government research labs to study drying processes and to develop new products.

Spray drying and encapsulation

Spray drying and encapsulation are processes used in the laboratory to create dry, powdered forms of liquids or semi-solids. These techniques have a wide range of uses, including preserving and stabilizing sensitive materials, improving the handling and storage of materials, and creating precise dosage forms for drugs and other products.

Spray drying involves atomizing a liquid or semi-solid into a fine mist, which is then dried using hot air or another drying agent. The resulting powdered product can be easily stored and transported, and can be reconstituted by adding water or another solvent. Spray drying is often used to preserve perishable materials, such as foods, pharmaceuticals, and biological samples, and to create dry forms of products such as detergents, pigments, and coatings.

Encapsulation involves enclosing a material in a protective coating or shell, which can be made from a variety of materials such as polymers, sugars, or proteins. Encapsulation can be used to protect sensitive materials from the environment, to improve their stability and shelf life, and to control the release of active ingredients. Encapsulation is commonly used in the food, pharmaceutical, and chemical industries, and has a wide range of applications, including drug delivery, food fortification, and pest control.

Both spray drying and encapsulation can be used to improve the handling and storage of materials, and to create precise dosage forms for drugs and other products. These techniques can also be used in combination with other processing methods, such as blending and granulation, to create customized products with specific physical and chemical properties.

What is the process of spray?

The process of spray drying involves atomizing a liquid feed into a fine mist or spray, and then drying the droplets by contact with hot air to form a solid powder.

The basic steps of the spray drying process are as follows:

Preparation of the liquid feed: Mixing and dissolving the material in a solvent or in other solution of carrier material .The liquid with the feed is prepared by mixing the desired ingredients in the appropriate proportions. It may also be necessary to adjust the pH, viscosity, or other properties of the feed to ensure that it can be atomized and dried effectively.

Atomization: The liquid feed is atomized and sprayed into a drying chamber with hot steam using an atomizer, such as a rotary atomizer, nozzle atomizer, or fluidized bed atomizer.

Drying: The atomized droplets are dried by contact with hot air in a drying chamber. The hot air evaporates the solvent in the droplets, leaving behind a solid powder.

Collection: The dried powder is collected using a collection system, such as a cyclone, bag filter, or centrifugal separator.

Packaging: The dried powder is packaged for storage or distribution.

In addition to these basic steps, the spray drying process may also involve pre-treatment of the liquid feed, such as filtration or heat sterilization, and post-treatment of the dried powder, such as sieving or coating.

Particle quality, in terms of morphology, shapes and structures depends on the substance properties, spray dryer design slow/fast drying of the process.

Maintenance of Laboratory spray dryers

Proper maintenance is essential to ensure the safe and efficient operation of a laboratory spray dryer. Here are some key maintenance tasks that should be performed regularly:

Cleaning: The drying chamber, atomizer, and collection system should be cleaned regularly to prevent build-up of product residues, which can affect the quality of the dried powder and lead to equipment malfunctions.

Lubrication: Moving parts such as bearings and gears should be lubricated according to the manufacturer’s recommendations to reduce wear and prolong the life of the equipment.

Inspection: The spray dryer should be inspected regularly for signs of wear or damage, and any defects should be repaired promptly to prevent further deterioration.

Calibration: The operating parameters of the spray dryer, such as the atomization rate, drying temperature, and airflow rate, should be calibrated regularly to ensure that the drying process is consistent and efficient.

Replacement of consumables: Wear items such as gaskets, seals, and filters should be replaced when they become worn or damaged to ensure that the equipment is operating at peak performance.

It is important to follow the manufacturer’s recommended maintenance schedule and procedures to ensure the safe and effective operation of the spray dryer. In addition, it is a good idea to keep detailed maintenance records to track the history of the equipment and facilitate troubleshooting.

In conclusion, Laboratory Spray Dryers are important and significant laboratory equipment in laboratories. Choose the most suitable for you.